1. Bolt/Stud Design

Select bolts of appropriate material according to the design conditions, and calculate the bolt area required to meet the gasket pre-tightening state and operating state compression force. The actually configured bolt area should not be less than the calculated area. The principle of bolt design is to determine the smaller bolt center circle diameter. The requirements can be met by selecting appropriate bolt specifications and quantities.

2. Gasket design

This is the basis of flange connection design. The appropriate type and material of the gasket should be selected according to the design conditions and the medium used, and the size (inner diameter, outer diameter, thickness) of the gasket should be determined.

Then calculate the compression force of the gasket in the preloaded state and the operating state.

3. Flange body design

Flange design is divided into two cases according to internal pressure and external pressure. Flanges subjected to external pressure can be designed according to the calculation method of flanges subjected to internal pressure, but the operating torque of the calculated flange is slightly different.

① There are two calculation methods for narrow flanges, namely, calculation based on loose flanges and calculation based on integral flanges. Arbitrary flanges are usually calculated as integral flanges, and can be simplified as loose flanges when certain conditions are met.

②The calculation of the loose flange is relatively simple, and the thickness of the flange can be calculated at one time. The design of the overall flange needs to be completed by assuming the structural dimensions of each part and performing repeated trial calculations.

③ For integral flanges, first assume the dimensions of the flange taper neck and flange ring according to the structural conditions of the equipment. Then calculate the moment and various stresses that the flange bears. When there is a large difference between each stress and the corresponding allowable stress, the originally set flange size should be adjusted, and the above calculation should be repeated until each stress is less than the respective allowable stress and the difference is not large, which is a reasonable design.

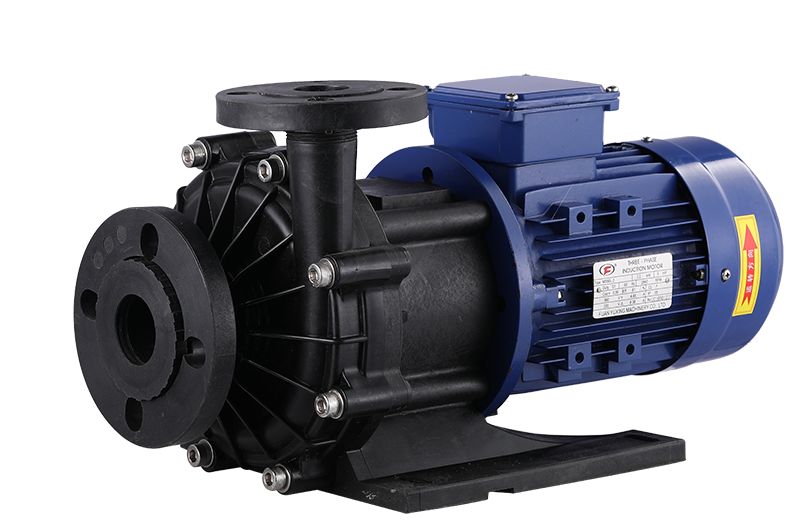

2. What are the types of acid and alkali resistant magnetic pump flanges?

1. According to the connection between the flange and the cylinder, it is divided into a loop flange, a threaded connection flange, a socket welding flange, a flat welding flange and a butt welding flange.

2. Pressure vessel flanges are divided into general flanges and reverse flanges according to the overall structure.

3. According to the arrangement of the gasket, it is divided into two categories: narrow flange and wide flange.

Post time: Aug-01-2023